What is aluminum honeycomb panels?

· June 11,22

Experiencef the magic of Luxprin Honeycomb Composite Panels boast system components that are bonded in a continuous process for reinforced strength.

Luxprin's Honeycomb Aluminium Panels offer excellent resilience and toughness by showcasing exceptional peel strength and toughness.

Unlike other Honeycomb Panels, it never becomes hard or brittle. Having great tensile strength of the cover sheets, beautiful aesthetics features and outstanding processing qualities, Luxprin Honeycomb Aluminium Panels have become the favourite of Architects, Planners and Designers.

Luxprin's Honeycomb Aluminium Panels are also extremely light in weight, yet it has high rigidity.

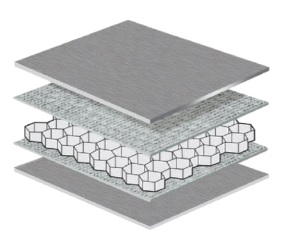

The secret lies in our PU/Epoxy based -2K for better bonding and strength that brings together the system components like the Aluminium Core and the coil-coated Aluminium Cover Sheets. It is ideal to be used as a Facade material in Architecture and False Ceilings in Interior Constructions.

Luxprin Aluminium honeycomb core is one of the most widely used high performance honeycomb materials; chosen for its excellent strength to weight ratio (the best of all core materials) and bonding characteristics.

Luxprin Aluminium honeycomb is used extensively in the motorsport, marine and aerospace industries and increasing now in construction industry where reducing weight whilst maintaining or improving the strength of a composite is of key importance.

In its un-expanded (block) form aluminium honeycomb is also very compact and easy to ship cost effectively and without risk of damage. Un-expanded blocks can be easily expanded into their full sheet form without the need for sophisticated equipment.

Like all core materials aluminium honeycomb is designed to be sandwiched between two skins of material to create a sandwich panel. By creating distance between the two skins and ensuring that these skins cannot move relative to each other great mechanical advantage is gained making for very stiff panels with only minimal increase in weight.

Luxprin Lightweight structure:

High tensile strength

Excellent structural stability

Superior heat and sound insulation effect

High surface smoothness

Vibration resistance

High moisture resistance and corrosion resistance

Nonflammable

Recyclable